A large brewery with several locations in Italy implemented a CIP optimization for 100 tanks together with Lechler. Prior to the optimization, static spray balls were used for cleaning.

PROJECT GOALS

- Reduce water consumption in the CIP

- Increase sustainability aspect

- Improve efficiency

CHALLENGES

- Detailed identification of technical requirements in several customer visits on site

- Creation of a draft to dimension the process based on Lechler's experience, including tests for effectiveness in several demonstration runs

SOLUTION

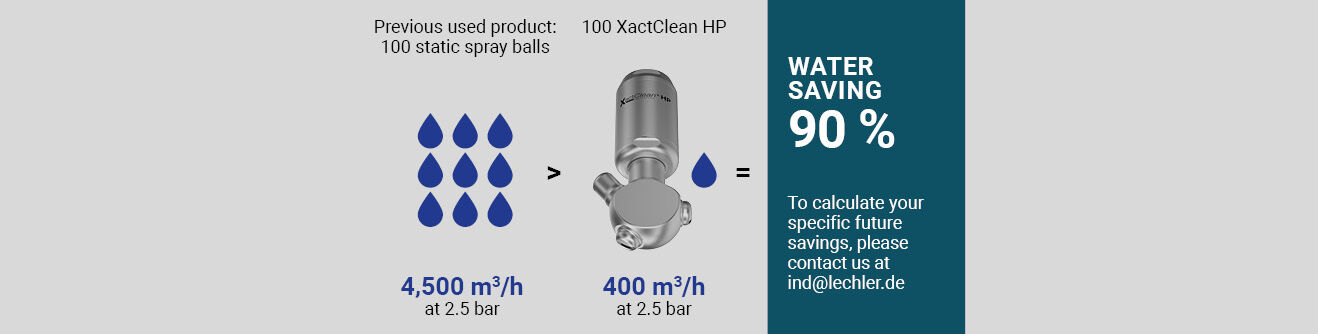

- Replacement of spray balls by Lechler XactClean HP nozzles, series 5S3

- Lechler TankClean software as a support for comparing the efficiency of spray balls and XactClean HP nozzles

CUSTOMER BENEFITS

- Achievement of significant savings in water, energy and chemicals

- Water savings achieved by the XactClean HP nozzles have a significant impact on the customer sustainability and financial targets

We are committed to responsibility and sustainability. Our products support you on your way to achieve your own sustainability goals.

Contact

Lechler Spray Technology Sdn. Bhd., MalaysiaBusiness Division General IndustryPhone +603 6142 1288 (General Line)Fax +603 6156 1153info(at)lechler.com.my