Gas cleaning (scrubbing)

Customized gas cleaning solutions for spray applications in scrubbers

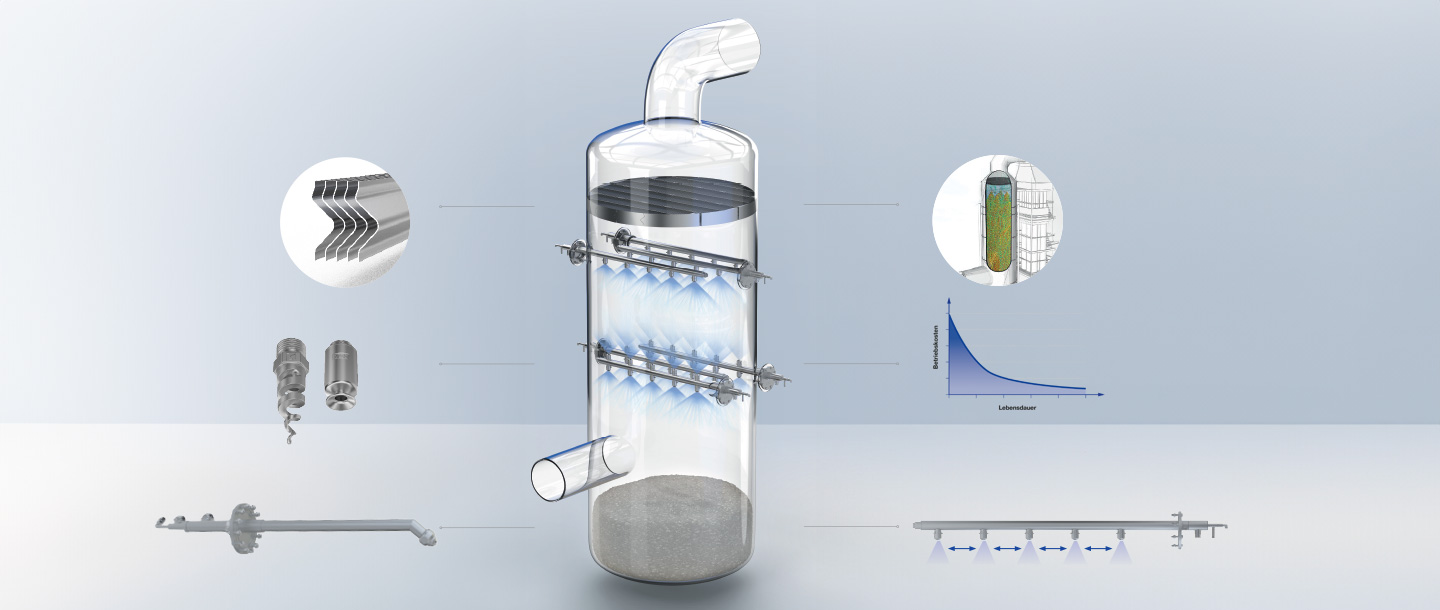

Efficient gas cleaning is essential for protecting the environment and reducing harmful emissions. At Lechler, we have extensive expertise and know exactly how and where droplets need to be introduced and precisely separated in the gas cleaning process. This is the only way to ensure an efficient gas cleaning process and achieve the maximum cleaning effect.

Many control variables for maximum scrubbing efficiency

Lechler is the only company to offer a complete portfolio of nozzles and droplet separators. Comprehensive services from engineering services to complex flow simulations complete our offer for gas cleaning applications. This is why Lechler is the preferred partner for spray applications in scrubbers.

One-stop shop: Lechler spray solutions for gas cleaning and scrubbers

Scrubber types

Different scrubber types are recommended depending on the application. The nozzle selection and positioning are selected for their efficiency. Here, Lechler does not just provide support as a supplier but also assists with its extensive experience in the planning and design of scrubbers.

Spray scrubber

Spray scrubbers atomize the washing liquid by means of several spray nozzles and generate a large reactive surface area. They are characterized by lower installation and maintenance costs as well as lower pressure losses.

Venturi scrubber

With this special form of a spray scrubber, the gas is routed through a narrow section into which the washing liquid is injected. Dirt particles are effectively separated due to higher flow velocity. Venturi scrubbers require less washing liquid than conventional spray scrubbers but are less effective for the separation of smaller particles.

Packed-bed scrubber

With packed-bed scrubbers, the gas is routed through packing material whose large surface area is wetted with the washing fluid. This scrubber type removes pollutants very effectively but requires a lot of space and maintenance. High pressure losses have to be taken into account in calculations due to the design principle. Clogging may also occur.

Corresponding products

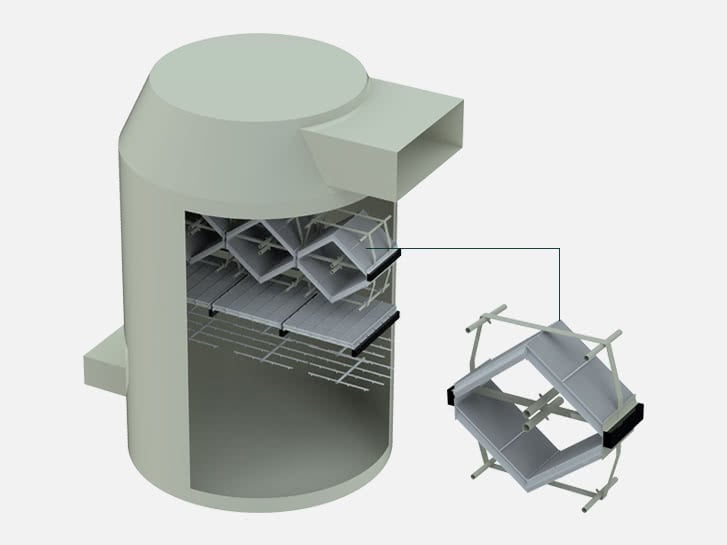

Lechler droplet separator systems

Modular, compact, combinable and efficient.

Different Lechler droplet separator systems can be combined with each other, depending on efficiency and space requirements.

Lechler TwinAbsorb and TwinAbsorbPRO

Double full or double hollow cone nozzles for wet flue gas desulphurisation

The innovative technology of Lechler TwinAbsorb nozzles ensure for an efficient flue gas cleaning and reliable SO2 separation.

Series 419 "FreeFlow"

Clogging free spraying with the new full cone nozzles FreeFlow

The unique interior design of the FreeFlow enables the flow of bigger particles and therefore the use of contaminated or fibrous liquids.

Series 4Fx "HelixFlow"

Spiral full cone nozzle

The spiral nozzle impresses with its robust and maintenance-free design, which makes it ideal for use in flue gas desulphurization, cooling and gas humidification.

What can Lechler do for you? Talk to us!

We will gladly help you make your scrubbers even more efficient. You will be amazed at how much optimization potential there is in your systems. We will be happy to advise you free of charge.